Contents Cleaning and Structural Restoration after a Fire

Contents Cleaning and Structural Restoration after a Fire

Introduction

If you were to remove the roof of an imaginary home, turn it upside down and shake it, most items that fall out are considered contents.

Examples include:

- Furniture

- Artwork

- Clothing

- Utensils / kitchenware

- Computers

- TVs

Did you know that many contents that are affected by smoke and soot can be fully restored?

While there are several nuanced factors that play into the ease or difficulty of restoration, such as:

- Type of fire (plastic, wood, rubber)

- Duration of time between the fire occurring and when the content is cleaned

- Proximity to heat (blistering of wood furniture, melting of plastic)

- Air pressure generated by the fire

- Type of material being cleaned (cotton, polyester, wool, silk)

- Electrostatic attraction of soot to metal

How porous your contents are will play a vital role in determining the probable success of the restoration. The more porous a material is, the more smoke it can absorb; the less porous, the less odour it can absorb.

There are three main categories, with examples of contents and building materials below:

- Porous

- Teddy bear

- Clothing

- Area rugs

- Semi-Porous

- Paper

- Photographs

- Un-sealed wood such as cutting boards

- Non-Porous

- Metal utensils

- Coffee cups

- Sealed wood such as dining room table, varnished coffee table

Generally speaking, non-porous materials have the highest restoration success rate, and porous has the lowest, but don’t rule out all porous materials because many of those can also be cleaned!

WINMAR® Kootenay begins the content restoration process by photo inventorying all contents in your home to document their current condition. During this inventory, we will make note of any existing and new damages.

We then carefully pre-condition the contents using HEPA vacuums and lambswool dusters to remove any loose soot from the surface so it won’t be “pressed” into the item during handling. Once items are pre-conditioned, we carefully pad and pack them into boxes and transport them to our state-of-the-art facility in Cranbrook, BC.

Photo of restoration technician boxing contents on a fire loss

Once at our facility, we start by processing porous items first because time is of the essence. The longer an odour remains in the item, the harder it is to get out. Using our soft content cleaning system, the items are cleaned thoroughly, odour tested, and then carefully hung to dry in a dehumidified room. During the drying process, we avoid using regular clothes dryers, which may cause the garment to shrink.

Once the items are dried, they are subjected to a 5-stage deodorization system in a sealed chamber where the various stages physically remove the odour. Contrary to most air fresheners that simply mask the unwanted scent with a more powerful scent, our process changes the odour particle on a molecular level to ensure your favourite pair of jeans doesn’t smell like smoke or chemicals. Science is magic!

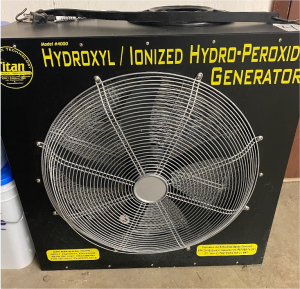

Photo of a hydroxyl generator, just one of our 5-step deodorization process

When the deodorization is complete, our trained content restoration technicians then test the item for odour one more time, prior to carefully packaging it up for storage until it is ready to be returned to your newly restored property. As the items are being packaged, our photo inventory is updated with post-cleaning photos so the new condition of the item is documented.

Next, semi-porous items are processed by hand or small power tools using special cleaners, applicators, and a lot of attention to detail. Sometimes wood surfaces may receive a varnish or smoke seal after processing to add an additional layer of protection. If there is a sentimental, antique, or irreplaceable item for example a coffee table that is blistered due to heat or charred due to fire, we can send it to trusted partners in Calgary or Kelowna who specialize in antique furniture restoration, and they will restore it to pre-loss condition. Some insurance policies cover this special request.

Lastly, non-porous items are processed though our ultrasonic cleaning line. Due to the acidity of soot, metallic items will begin to oxidize the moment the fire occurs. So although we triage porous items first, the clock is still ticking when we get to non-porous items. Using tiny, microscopic bubbles and a process called cavitation, our system physically removes soot from the item being cleaned in as little as 5 minutes.

Photo of two coffee mugs that looked identical prior to one being processed by our ultrasonic cleaner

If an item cannot be restored at our facility, it is documented as non-restorable or “NR” and most policies will then provide a cash settlement for the item at the end of the restoration process.

Structure Restoration

The way we restore the structure follows a similar approach as contents. We categorize the building materials into the 3 categories of porosity.

- Porous – Drywall

- Semi-porous – 2×4 wall studs and sheathing

- Non-porous – Metal wall stud

The traditional process:

- Precondition surface with HEPA vacuum or similar method

- Dry-clean surface with chem-sponge or similar method

- Wet-clean surface with degreasers and surfactants

- Deodorize (5 steps), same as for contents

- Apply smoke-seal

Photo of chem-sponge being used to clean soot from drywall – can you spot the difference?

Reconstruction

Once the fire restoration is complete, your home now becomes a standard reconstruction site.

This is the stage where our journeyman carpenters and subtrades for electrical, flooring, and plumbing will come into your home to reconstruct it back the way it was.

Photo of a carpenter reconstructing a property

While most policies cover reconstruction to pre-loss condition, this stage of the project is an opportunity for homeowners to update their flooring style, change their paint colors, or even completely renovate their home by removing and adding walls.

Working closely with your project manager, you will be asked to choose colors, materials, and complete inspections throughout the project.

Once the reconstruction is complete, your contents will be returned to your property and unboxed for you, thus wrapping up the fire restoration process.

Mini-storage unit before restoration

Mini-storage unit after restoration