What is dry ice blasting and why is it used?

What is dry ice blasting and why is it used?

What is dry ice blasting?

Dry ice is used by WINMAR® Kootenay to safely remove contamination or unwanted coatings from surfaces. Forms of contamination may include fire soot, mold root staining, graffiti, grease, rust, etc.)

When the rice-sized dry ice pellets are blasted against a surface, they disintegrate and change to carbon dioxide gas through a process called sublimation. This is advantageous to traditional blasting media such as sand, soda, or glass, which require cleanup of the secondary waste afterwards. Often, the blasting media ends up inside HVAC systems, and is distributed throughout the entire facility if the contractor is not careful.

Photo of dry ice pellets

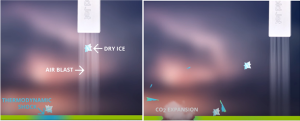

The contamination, along with other debris, is removed through a combination of the following 4 methods:

- High volume and pressure of compressed air

- Direct impact by rice-sized pellets of dry ice

- Thermodynamic shock as the sublimation occurs instantly

- Because the mass of the substrate exceeds the mass of the contaminant, once contacted by dry ice the contaminant will cool at a significantly faster rate than the substrate, causing thermal contraction, and thus imposing a shear force against the bonding plane to the substrate to separate the contaminant from the substrate

- Dry ice is -79 degrees centigrade, and this thermal shock helps remove contaminants

- Rapid CO2 expansion

Projects that benefit from dry ice blasting

- Heavy duty machinery cleaning before maintenance

- Precision cleaning IT equipment

- Restoration of heritage items (books, woodwork, antique conservation)

- Food processing plants

- Manufacturing facilities

- Graffiti removal

- Rust restoration

- Building restoration including fire, and mould projects

Fire Remediation

When restoring property after a fire, many contractors rely on manual labour and old-fashioned techniques. Although this is a tried-and-true approach, it is very time consuming. When the primary goal is to minimize business interruption, this outdated method will cause a significant bottleneck on the critical path of your restoration schedule.

Traditional method:

- Precondition surface with HEPA vacuum (LABOUR INTENSIVE)

- Dry-clean surface with chem-sponge (LABOUR INTENSIVE)

- Wet-clean surface with degreasers and surfactants (LABOUR INTENSIVE)

- Deodorize

- Apply smoke-seal

Dry Ice Method

- Blast with pelletized CO2 (VERY FAST)

- Deodorize

- Apply smoke seal

WINMAR® Kootenay technician blasting soot from a wood surface

Before – Underside of roof deck

After – Underside of roof deck

Mould Remediation

When restoring property that has been impacted by active mould growth, we have to decide if the mould can be removed along with the material it is growing on, or if it must be separated from the material altogether.

For example, when we encounter mould on porous building materials such as drywall, we remove the material altogether. However, when mould is found on wood framing members such as floor joists or roof trusses, we have to restore these materials in place because removing the trusses would be costly, time consuming, and may cause more damage than the mould itself.

One of the most difficult and labour-intensive aspects of any mould remediation project involve removal of mould hyphae (root staining). To learn more about mould structures, check out our blog titled “I THINK MY HOME HAS A MOULD PROBLEM”.

Typical mould root staining in an attic

Removal of root staining is typically completed with wire brushing, which as you can imagine takes a tremendous amount of time to wire brush all surfaces of trusses in an attic. With dry ice however, we can completely remove the staining in a typical attic in 1-2 days with 2 workers, vs. a full week with a crew of 5.

Safety

As with any abrasive blasting technique, dry ice blasting is not without its dangers. Through extensive training, policies, and procedures, the team at WINMAR® Kootenay effectively manages all risks to restore your property both safely, and efficiently.

The primary safety concern is ventilation. Because CO2 is heavier than air, it will displace oxygen from the area. We manage this hazard through installation of powerful ventilation fans, and our workers use breathing air through a hose located outside the work area, also called a “supplied air system”. As an extra precaution, our technicians wear oxygen monitors and always have a spotter located in a safe area.

Typical supplied air system

WINMAR® Kootenay technician wearing supplied air respirator, and oxygen monitor

Disadvantages

While dry ice blasting can be very cost-effective on medium to large projects, it is not always the best choice for small projects such as a bathroom mould remediation, or work where access is intermittent over several days (non-continuous).

Because setup of our equipment requires large tow-behind air compressors, equipment mobilization and calibration, it is sometimes better to use traditional methods instead of dry ice blasting.

If we have to start and stop several times, the equipment mobilization and demobilization can be counter-productive.

Depending on the location of your project, another disadvantage to dry ice is that the ice may have to be transported from Calgary or Vancouver in 500lb totes. During transport, the ice slowly sublimates (around 8% per day) and essentially disappears before it gets to your location for us to use.

With the experience of WINMAR® Kootenay’s project managers, we can help structure your project to avoid these downfalls, even working around restrictive project constraints such as noise, public access, or fast-tracked schedules.

Conclusion

Property restoration has existed for hundreds of years, but just because a method of restoration is effective, doesn’t necessarily mean it is the best solution for the project.

Dry ice blasting is a modern method that is safe, cost effective, and efficient.

WINMAR® Kootenay serves the entire province of BC. If you have a project in mind that you believe could benefit from dry ice blasting, contact us today at info@kootenay.winmar.ca